products

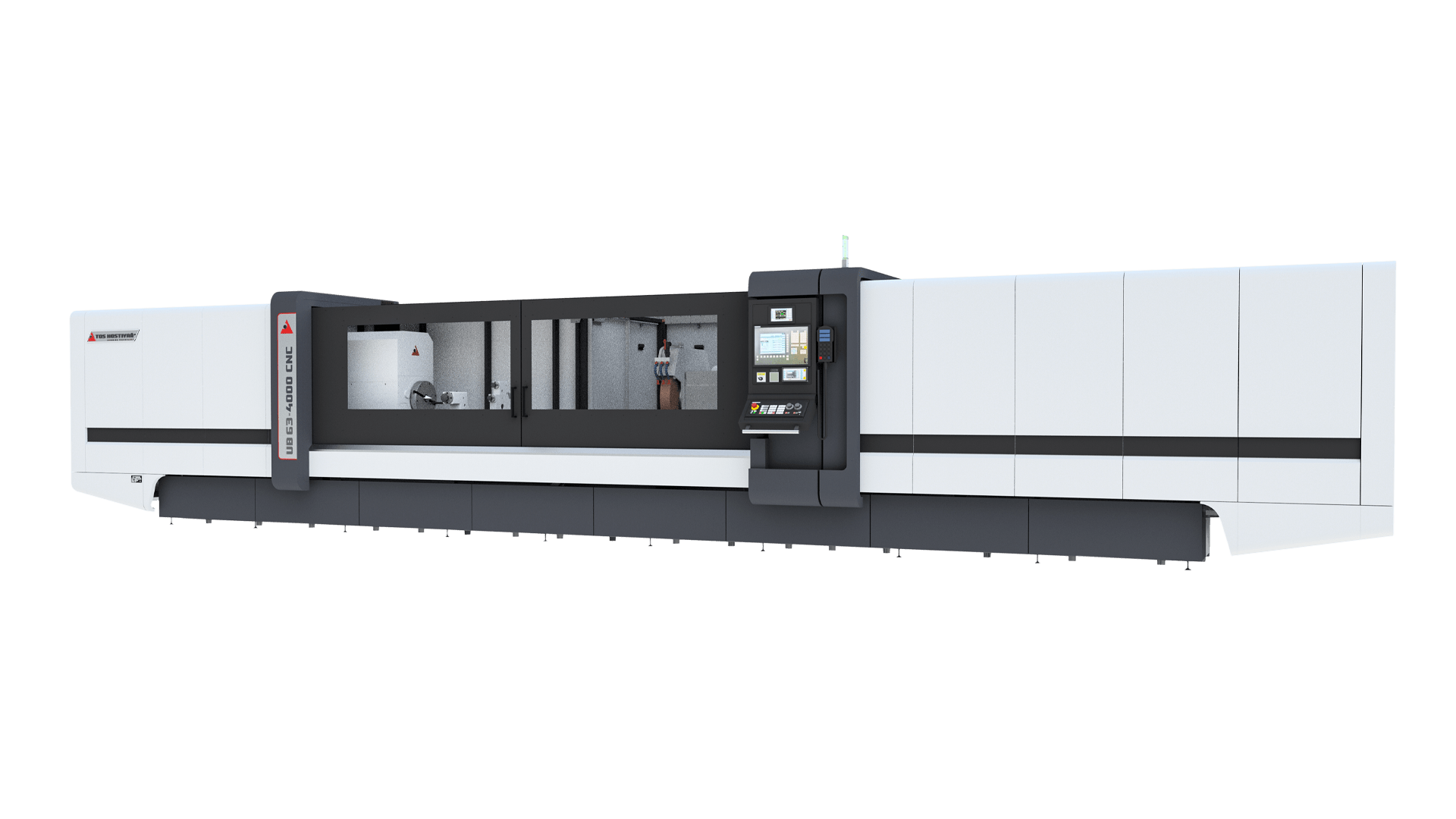

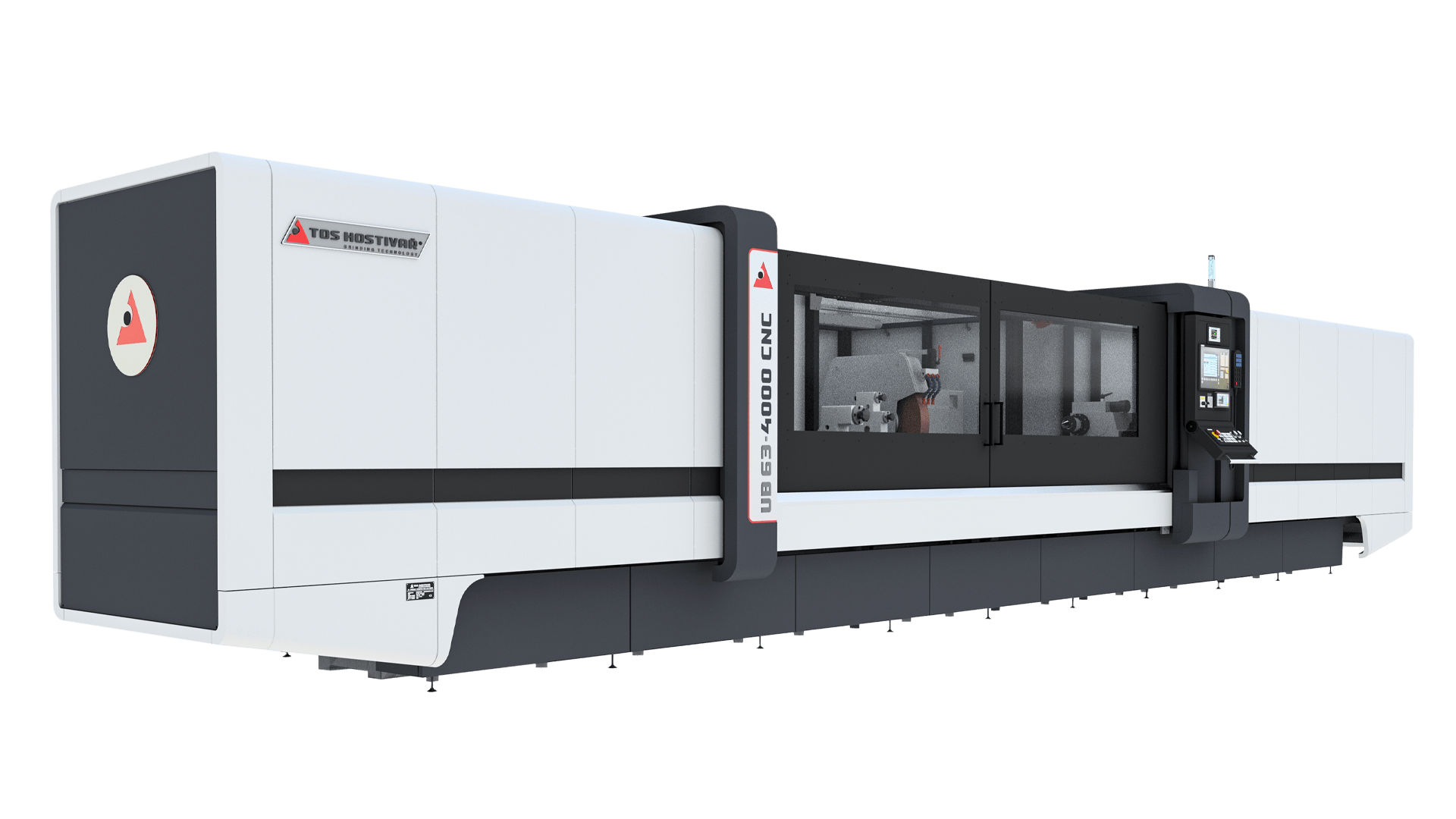

Universal Grinding Machine

UB 63 – 3 000 kg

| Distance between centers | 2,000; 3,000; 4,000; 5,000; 6 000 | mm |

| Max. swing diameter | 630, 850, 900 | mm |

| Minimum X axis increment | 0.001 | mm |

| Minimum Z axis increment | 0.005 (0.001) | mm |

| Grinding wheel peripheral velocity | 25 – 45 | m/s |

| Max. weight between centers | 2 500 – 3 000 | kg |

| Max. workpiece weight incl. fixture – overhanging | 250 | kg |

| Grinding wheel diameter | 750 | mm |

| Spindle power | 22 | kW |

| CNC control system | Siemens Sinumerik ONE or Kavalír NXCS |

Characteristics

Universal grinding machines UB 63 – 3,000 kg form a number of our largest machine tools. UB 63 – 3,300 kg are based on the basis of time-tested design, complemented by modern features. These grinding machine are used for grinding of workpieces max. Diameter of 630, 850 and 900 mm and a max. Length of 6000 mm, clampend between centers or overhung in a chuck with the possibility to use of internal grinding device. During grinding, the machines can be controlled manually or work in fully automatic grinding cycle (grinding multiple diameters (multicycle), plunge grinding or lengthwise grinding, grinding of convex or concave diameters with automatic grinding wheel dressing). Workpieces are clamped between centers, overhung in chuck or on a magnetic permanent plate. The machines are intended for precise and high-performance grinding of individual pieces but also for large series of workpieces.

- Flexible grinding of medium-heavy to heavy cylinders and shafts.

- Heavy machine design with variable grinding wheel location.

- Design with one or two grinding headstocks.

- Control system CNC – Siemens Sinumerik ONE or Kavalír NXCS

- Grinding spindles with hydro-dynamic suspension or on roller bearings.

- Partial or full cover of machine with grinding mist exhaustion.

- SBS Dynamic balancing system of grinding wheel.

- Measuring, cooling and electric systems by world leading manufacturers.

Photo gallery

Standard accessories

- Coolant splash guards – partially covering with a manual-controlled door.

- Tailstock mounted wheel dresser (without diamond).

- Fixed tips (2pcs).

- Sedimentation cooling equipment.

- Electric foot pedal for pneumatic tailstock control.

- Puller of grinding wheel flange.

- Suspension of grinding wheel flange.

- Set of pads for bed leveling.

- Balancing arbor with a nut.

- Tools for operating of machine.

- LED lighting IP65.

- Technical documentation.

Special accessories

- Size gauge for longitudinal workpiece positioning.

- In-process measurement of workpiece diameter.

- SBS Automatic electro-dynamic balance system of the grinding wheel.

- Extra grinding wheel flange.

- Internal grinding att. complete incl. spindle and motor-drive.

- Closed steady rest actuated by hand.

- Tilting wheel dresser table mounted w/o diamond actuated by hand.

- Three jaw-chuck, incl. adapter plate.

- Permanent magnetic plate incl. adapter plate.

- Auxiliary rests with different diameter range.

- Side and angular dresser table mounted w/o diamond actuated by hand.

- Radius dresser table mounted w/o diamond actuated by hand.

- Att. for fine table swiveling with dial indicator.

- Water tank fitted with a magnetic or belt filter or a combination thereof.

- Wheel balancing stand.

- Set of chemical dowel screws for bed leveling.

- Unique system SmarTOS

Do not hesitate to contact us

TOS Hostivař s.r.o.

Rádiová 1431/2a

102 00 Praha 10

Czech republic