PRODUCTS

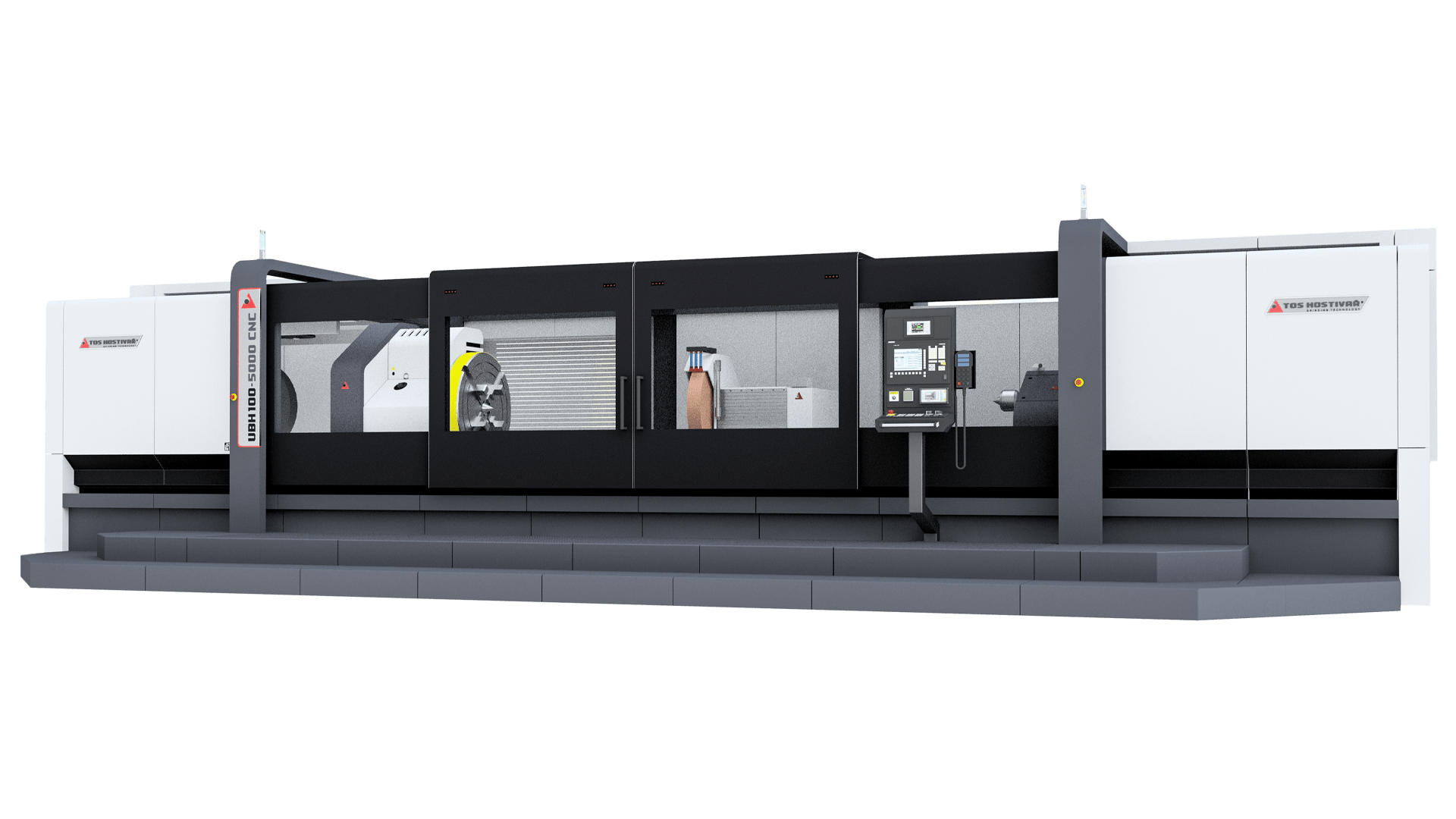

Universal Grinding Machine

UBH 100 – 9 000 kg

| Distance between pcenters | 4 000; 5 000; 6 000; 7 000; 8 000 |

mm |

| Max. swing diameter | 1 000 | mm |

| Minimum X axis increment | 0,001 | mm |

| Minimum Z axis increment | 0,002 | mm |

| Grinding wheel peripheral velocity | 25 – 50 | m/s |

| Max. weight between centers | 9 000 | kg |

| Grinding wheel diameter | 915 | mm |

| Grinding headstock spindle power | 30 | kW |

| CNC control system | Siemens Sinumerik ONE or Kavalír NXCS |

Download the product booklet

Characteristics

The UBH 100 CNC universal grinding machine is the heaviest machine produced by TOS Hostivař. Thanks to the concept with a grinding headstock moving in the X and Z axis, allows the workpiece to be clamped between points 8,000 mm long and weighing up to 9,000 kg.

It has a turning diameter of the workpiece clamped between the working headstock and the tailstock up to 1,000 mm. The modular concept of the machine allows any length configuration of the machine together with a large variability of optional accessories. Development of a UBH 100 CNC center CNC grinder in cooperation with CTU and RCMT.

- Temperature sensors for monitoring the thermal stability of the machine.

- The concept of separate front and rear bed.

- Advanced grinding spindle diagnostics using temperature and vibration sensor.

- Sealing of the grinding spindle with a labyrinth seal and sealing air.

- Rolling bearing of the grinding spindle in precision spindle bearings with permanent grease filling.

- Modular concept of grinding headstock.

Fotogalerie

Standard accessories

- A set of leveling washers and anchoring and push-out screws to level the machine.

- Flange for grinding wheel with Ø 915 mm, with clamping hole D = 305 mm and for wheel width in 76-155 mm.

- Balancing mandrel and nut.

- Grinding wheel flange puller.

- 2x Clamping tip Metric 100 1:20 with sintered carbide.

- Set of measuring jigs for bringing the machine into geometric accuracy:

Bed measuring plate (1x) / Jumper for measuring the rear bed (1x),

Measuring mandrel for working headstock (1x) / Measuring jig for grinding headstock (1x). - 2x Clamping tip Metric 100 1:20 with sintered carbide.

- Main tank for cooling emulsion 2000 l and pumping tank 650 l.

- A set of measuring jigs to bring a machine into geometric accuracy.

- Securing the machine during transport.

- Technical documentation:

complete machine operating instructions, control system operating instructions, machine accuracy protocol, electrical and inspection report, declaration of conformity.

Special accessories

- Two jaw open support: manually operated For diameters D = 250-350 / 350-450 / 450-550 mm

- Two jaw open support:

CNC control of vertical and horizontal jaws (U and V axis)

For diameters D = 250-350 / 350-450 / 450-550 mm. - Auxiliary, hydraulically operated, supports (2 pieces), with replaceable forks.

- Equipment of the main emulsion tank (2000 l) with a paper filter and a magnetic separator with a maximum flow of 200 l / min.

- Extraction of oil mist from the machine space:

2x Darwin 3000 (2x 3000 m3 / h). - Equipping the grinding headstock with a pneumatically tilting MARPOSS touch probe (or RENISHAW) for axial positioning of the ground piece.

- Equipping the grinding headstock with an autonomous electrodynamic device for balancing the grinding wheel during operation: Schmitt SBS (USA) with inserted control panel on the machine control panel, including AEMS Schmitt grinding monitoring (spark grinding, gap and crash control).

- Unique system SmarTOS

Do not hesitate to contact us

TOS Hostivař s.r.o.

Rádiová 1431/2a

102 00 Praha 10

Czech republic